Reference: CTG-LAB-205-25

A comprehensive review of the analysis certificate for Pyrolysis Oil (PYO) has been conducted. The conclusion is unequivocal: this product is not a conventional alternative fuel. Instead, it should be classified as a high-value blending component and a crude oil modifier with exceptional technical characteristics. Its true potential does not reside in competing on a one-to-one basis with diesel but in acting as a strategic molecule that resolves critical inefficiencies across the hydrocarbon value chain.

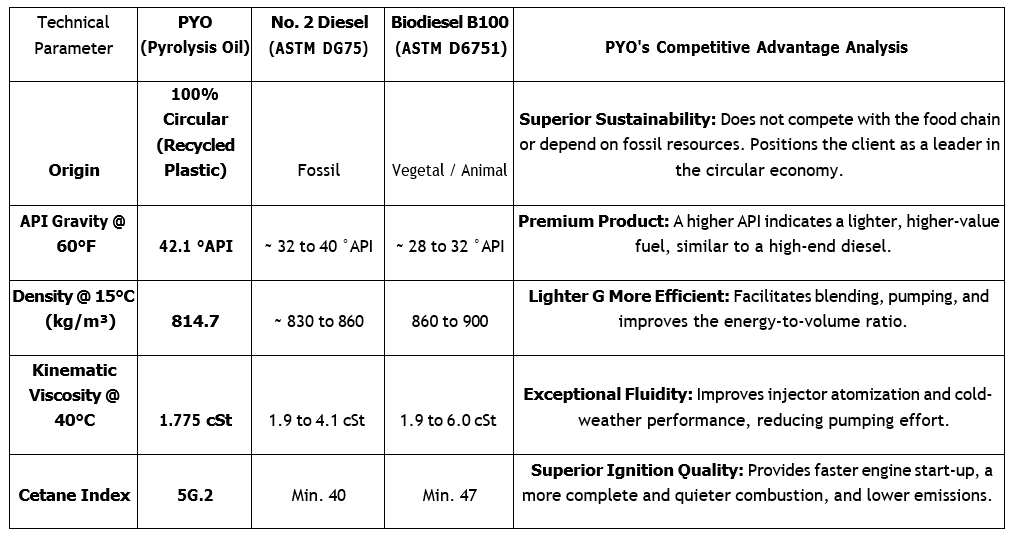

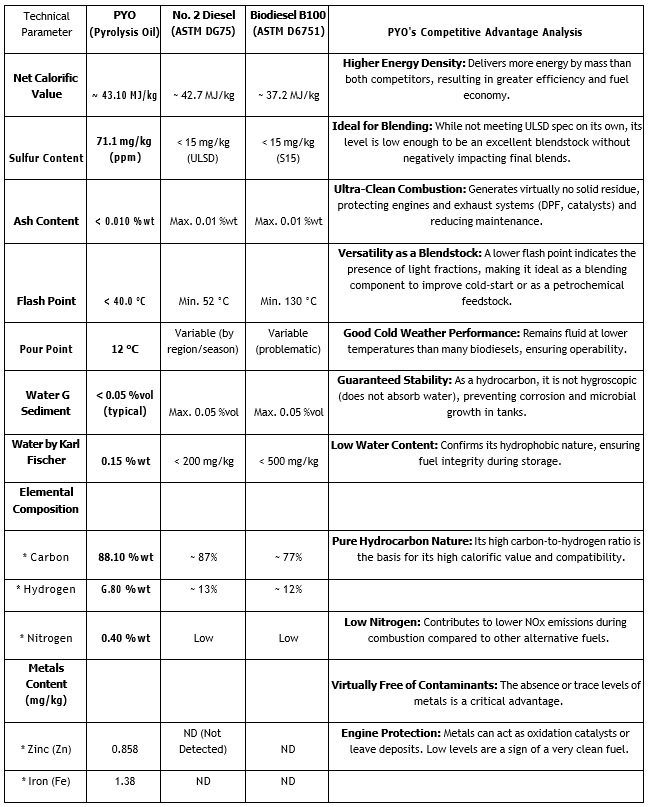

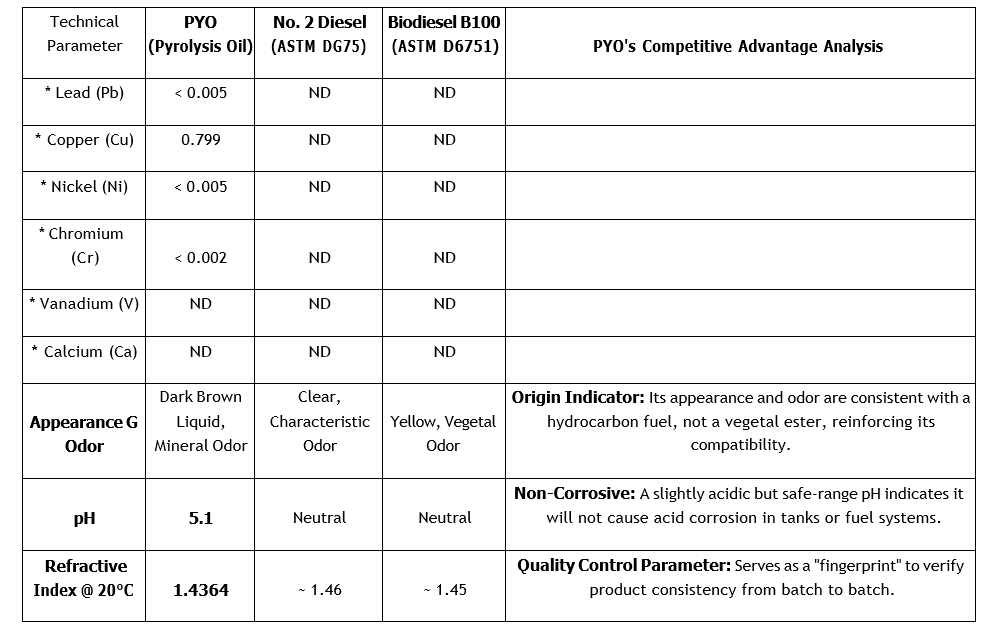

The following is a detailed parameter-based technical analysis emphasizing the strategic value of PYO:

These two parameters, when evaluated together, form the cornerstone of PYO’s value proposition. The presence of such a high API gravity combined with an extremely low viscosity is uncommon in materials not derived directly from distillation units.

Technical Analysis:

The measured viscosity is nearly half the minimum requirement for diesel fuel. As such, PYO functions as a super-fluidizer, with a blending impact that is exponential rather than linear when it comes to viscosity reduction.

Strategic Implications:

Upstream (Production): PYO presents an ideal solution for handling heavy and extra-heavy crude oils. Its use facilitates pumping operations—lowering operational expenditures (OPEX)—while simultaneously increasing the overall API of crude blends. This uplift directly enhances market value per barrel (as reflected in pricing benchmarks such as WTI and Brent), rendering the product effectively self-financing.

Midstream (Transport): Its low viscosity minimizes the need for pipeline heating and reduces pumping pressure requirements, thereby extending the operational lifespan of transport infrastructure.

Refining: PYO enables refiners to process heavier and more economically advantageous crude oils by blending, optimizing the refinery’s feedstock profile and improving operational flexibility.

A cetane index approaching 60 is considered exceptional, exceeding the standard levels found in most premium diesel fuels.

Technical Analysis:

A high cetane index reflects a short ignition delay, enabling more rapid, complete, and controlled combustion from the point of injection.

Strategic Implications:

PYO functions as a premium additive capable of elevating diesel fuel performance. A 10–20% blend of PYO into conventional diesel can increase the final cetane index by 2–4 points, effectively transforming baseline diesel into a high-performance product. This enables fuel distributors to create and commercialize premium diesel grades with improved margins using PYO as the differentiating component.

Despite being a product of pyrolysis, PYO’s chemical composition mirrors that of a clean distillate, highlighting its remarkable refinement.

Technical Analysis:

With sulfur levels measured at 71 ppm, PYO is compatible with ultra-low sulfur diesel (ULSD) standards. The absence of ash and trace metals—including vanadium, nickel, and calcium—is particularly noteworthy, as these elements are well-known catalyst poisons and harmful to exhaust after-treatment systems.

Strategic Implications:

Refinery Compatibility: PYO can be integrated into refinery streams without risk to catalytic units, protecting assets that represent investments worth hundreds of millions of dollars.

Engine Safety and Performance: The absence of ash ensures no deposits form within injectors, pistons, or turbochargers, positioning PYO as a clean fuel option that actively protects engine components—a compelling commercial argument.

Marine Fuel Blending: PYO serves as an optimal component in producing Very Low Sulphur Fuel Oil (VLSFO), compliant with the stringent IMO 2020 maritime emission regulations.

PYO exhibits a net calorific value greater than diesel and significantly higher than biodiesel.

Technical Analysis:

This energy density stems from a high carbon-to-hydrogen ratio and the absence of oxygen in the molecular structure—contrary to biodiesel, which consists of oxygenated esters.

Strategic Implications:

In combustion systems such as engines, boilers, or turbines, this translates to lower fuel consumption to produce an equivalent energy output. For major consumers—including freight operations, mining companies, and power generation facilities—a 5–10% reduction in fuel usage results in substantial operational cost savings.

PYO should no longer be marketed or positioned as a conventional oil or alternative fuel. Instead, it must be rebranded and promoted as a “Circular Hydrocarbon Improver.”

A bifurcated market strategy is recommended:

Solution-Based Selling (Upstream and Refining):

Instead of selling by volume (liters or tons), value should be framed around the performance enhancements provided: API uplift, viscosity reduction, and feedstock optimization. Pricing models should be linked to client outcomes—e.g., a percentage share of the increase in crude oil value per barrel.

Premium Additive Model (Fuel Distribution):

PYO should be offered as a branded additive (e.g., “PYO-BOOST”) that enhances cetane rating and promotes engine cleanliness. Fuel distributors can utilize this formulation to create high-performance diesel blends and premium product lines.

The additive represented by PYO belongs to a superior category of hydrocarbons. Its value is not defined by its production cost, but by its ability to enhance the efficiency, quality, and profitability of multi-million-dollar systems. PYO enables the creation of higher-value products through simple yet strategic blending processes.

Entities utilizing PYO are not adopting a substitute—they are integrating a performance upgrade across the hydrocarbon value chain.

Objective:

To provide a robust technical foundation for demonstrating the superiority and compatibility of PYO as a high-performance blending component or alternative fuel, benchmarked against current market standards.